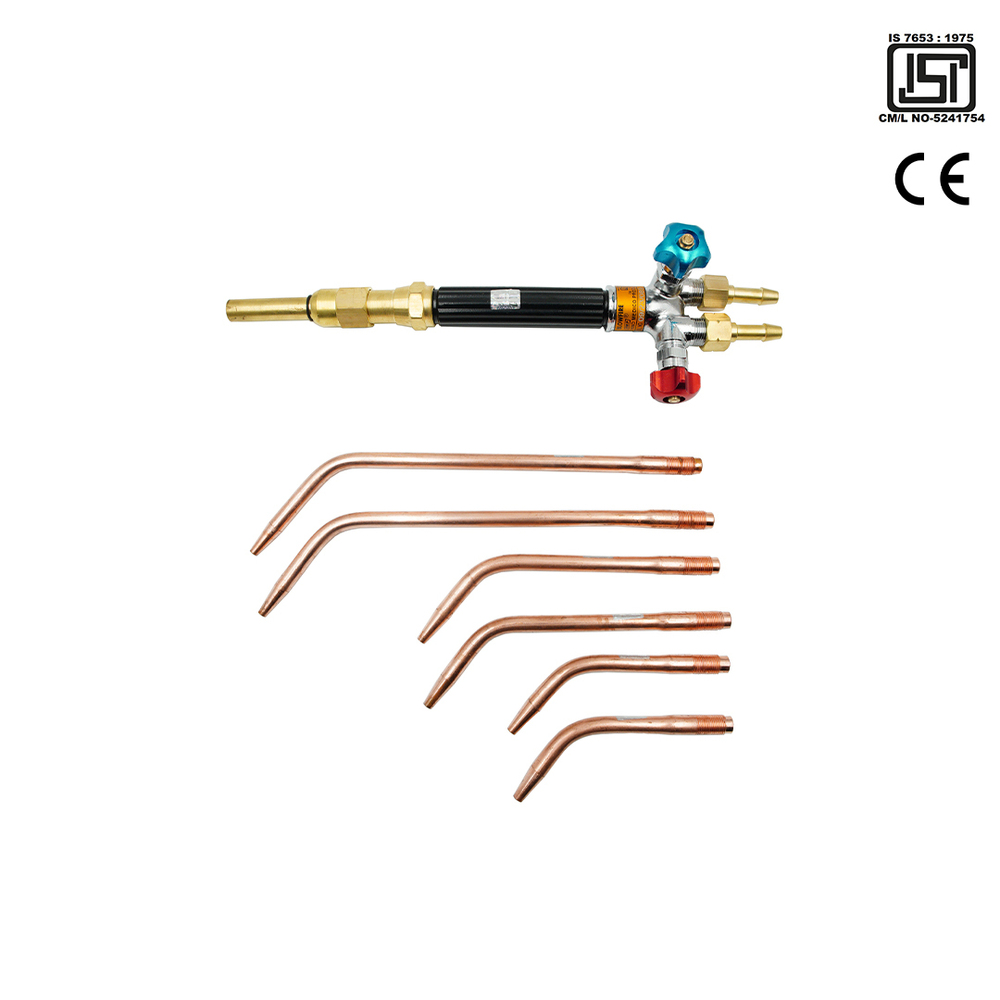

Upgrade your welding arsenal with the Manual Welding Blowpipe (BLOWFIRE)an ineffable fusion of optimum engineering and top-drawer materials, including brass, stainless steel, and copper alloys. Jump on this scarce opportunity to purchase a blowpipe that seamlessly adapts to Oxygen with LPG, Acetylene, or Hydrogen. Boasting an ergonomic, non-slip grip handle and interchangeable nozzles, BLOWFIRE delivers precision in industrial workshops, fabrication units, or automotive garages. Enjoy a polished, corrosion-resistant finish and built-in safety features, while lightweight construction ensures effortless control for general-purpose welding, brazing, or soldering applications.

Commercial Applications & User Guidance for BLOWFIRE

The Manual Welding Blowpipe (BLOWFIRE) stands as a go-to for industrial workshops, plumbing specialists, and automotive fabrication units. Widely used by skilled technicians and welders, its direction of use is straightforward: connect to the suitable fuel gas, manually ignite with flint or spark, and select the required nozzle for the job. Its ergonomic design and optimum build make it highly practical for heating, brazing, and general welding tasks, ensuring efficiency and safety every step of the way.

Sample Procurement & Export Market Details for BLOWFIRE

Premium samples of the BLOWFIRE manual welding blowpipe are available on request to assure product satisfaction before placing a purchase order. Our supply ability is robust, supporting both small and bulk requirements, and we pride ourselves in dispatching orders promptly. Catering extensively to major export markets worldwide, including Asia, Africa, and the Middle East, we accommodate individual box or bulk packaging based on client needs, upholding reliability through each stage of procurement and delivery.

FAQs of Manual Welding Blowpipe ( BLOWFIRE ):

Q: How do I use the Manual Welding Blowpipe (BLOWFIRE) for different applications?

A: To use the BLOWFIRE blowpipe, simply attach to your chosen fuel gas (Oxygen combined with LPG, Acetylene, or Hydrogen), select the appropriate nozzle size, manually ignite with a flint or spark, and begin your welding, brazing, or soldering task. Ensure safety by checking the built-in flashback arrestor if applicable.

Q: What materials are used in the construction of the BLOWFIRE blowpipe?

A: The BLOWFIRE is constructed from premium materials such as brass, stainless steel, and copper alloys, guaranteeing durability, corrosion resistance, and optimal performance even in demanding industrial environments.

Q: When can I request samples of the Manual Welding Blowpipe?

A: You may request samples of the BLOWFIRE blowpipe at any time. Samples are available to help you evaluate the product quality before placing a purchase order. Please contact us for specific sample dispatch timelines.

Q: Where is the BLOWFIRE blowpipe commonly used?

A: The BLOWFIRE blowpipe is commonly employed in industrial workshops, fabrication units, plumbing jobs, and automotive workshops for tasks like welding, heating, brazing, and soldering.

Q: What safety features does this welding blowpipe include?

A: For user safety, the BLOWFIRE is equipped with a built-in flashback arrestor (if applicable), ergonomic non-slip grip, and corrosion-resistant finish, reducing the risk of accidents while ensuring long-term usability.

Q: How does purchasing the BLOWFIRE benefit industrial operations?

A: Opting for BLOWFIRE ensures precise, efficient welding with a lightweight, easy-to-handle device. Its interchangeable nozzles and ergonomic design maximize versatility and minimize operator fatigue, leading to increased productivity.